As a Master Systems Integrator, we don't create hardware or software, we deploy it.

We are a team of engineers that integrate best-of-breed technologies, combined with experience and expertise to get buildings operating at peak performance and efficiency.

Our Solutions...

Building & Energy Analytics - Digital Facility Management

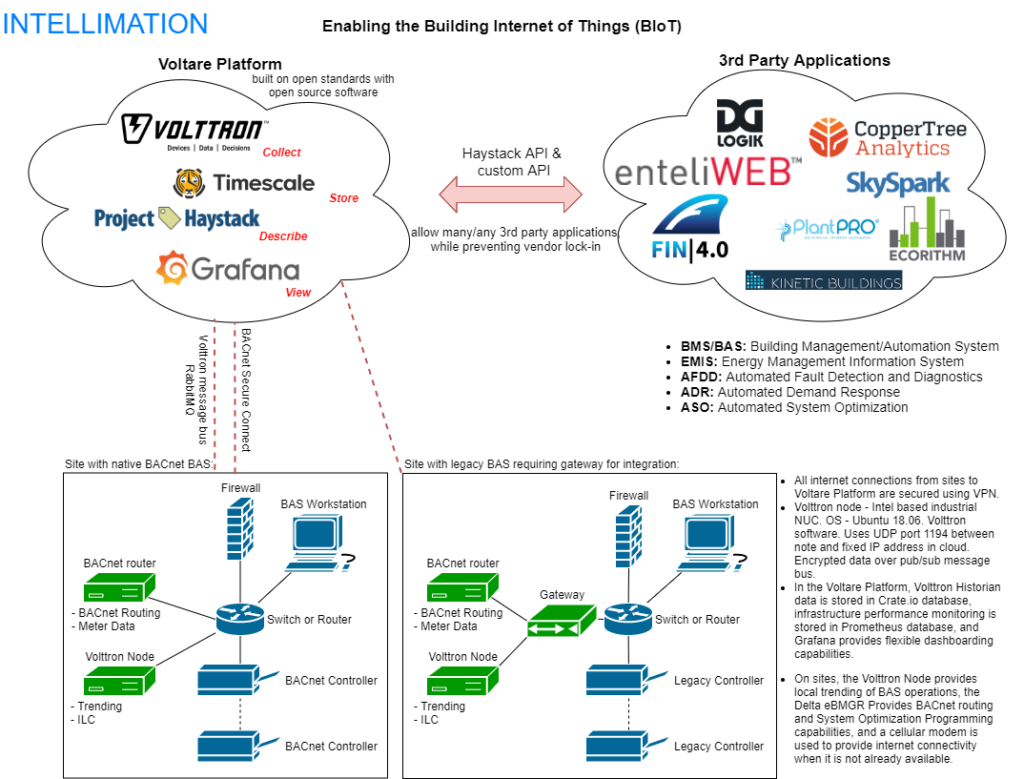

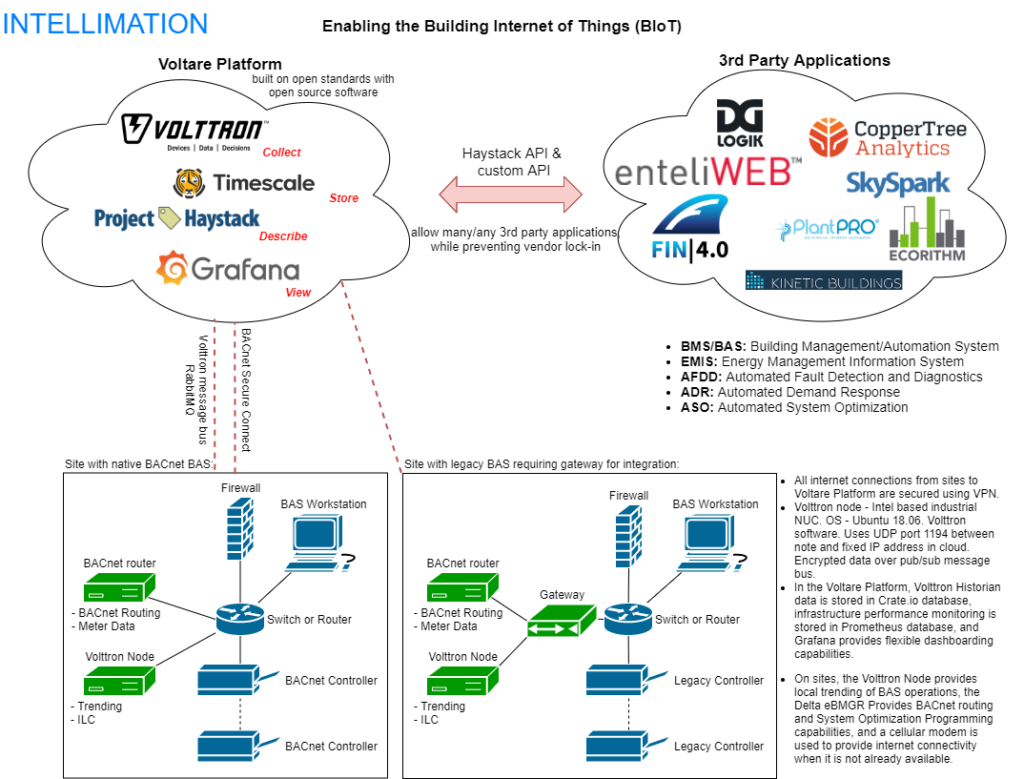

Intellimation deploys an open source middleware data acquisition, trending, semantic tagging, and archiving layer. This is inexpensive, vendor neutral, and allows the client flexibility and choice of applications.

Systems Integration

BAS and Meter data integration has gotten easier with open standards - BACnet. But, 30% of existing buildings have an older, legacy, proprietary BAS that requires a gateway to expose the data as BACnet.

Intellimation has never failed to integrate / gateway a proprietary protocol to BACnet. Our legacy integrations include...

- Johnson Controls N2 - Siemens P2 - Niagara AX - Trane BCU & Comm4 - Alerton - Andover - ASI | - Computrol - Carrier CCN - Barber-Colman ASD - Honeywell C-bus - LON - Modbus - Ethernet IP |

High Profile Integrations

- The Empire State Building - Johnson Controls

- Emory University - Siemens (proprietary P2 protocol) & Automated Logic

- Temple University - Siemens (proprietary P2 protocol)

- One Judicial Center (DC) - Niagara

- Chanin Building (NYC) - Johnson Controls (proprietary N2 protocol)

- Swarthmore College - Siemens Desigo

- Wake Tech Community College - Johnson Controls N1 & N2

Automatic System Optimization (ASO)

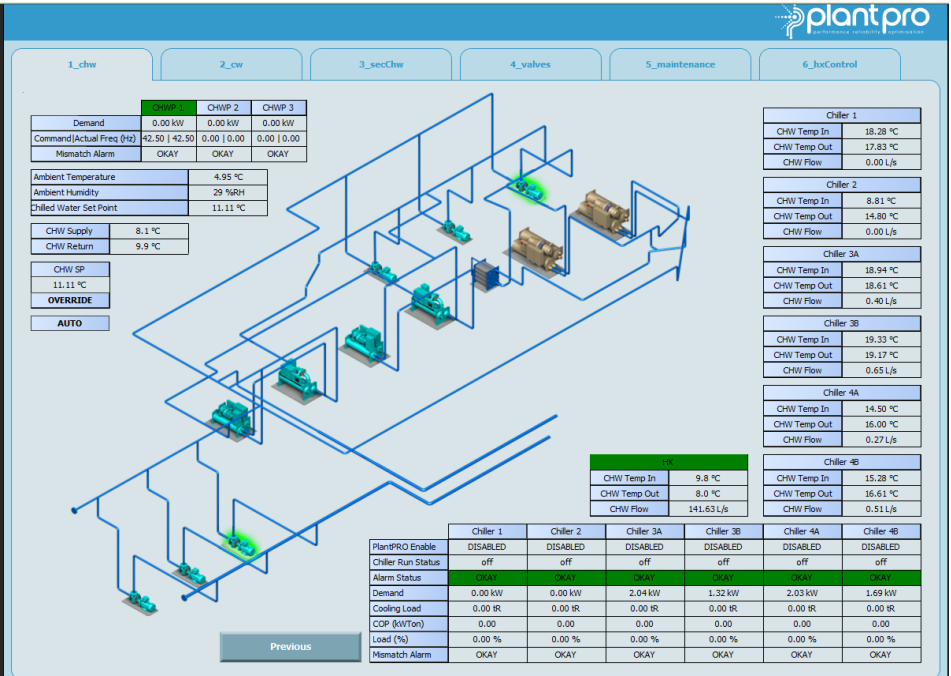

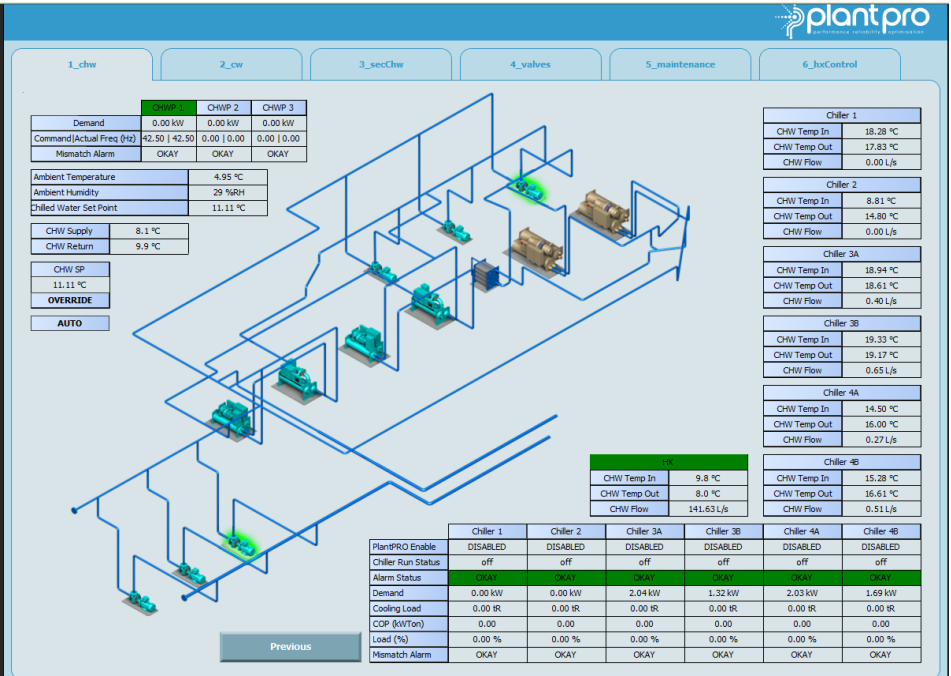

During every Monitoring Based - Data Driven retro-commissioning project, we always deploy advanced supervisory control algorithms, or optimizations. Sometimes we program these into the existing BAS or place a supervisory device with built-in algorithms.

Metering

You can't control what you don't measure. At Intellimation, we have deployed hundreds of nearly every type of meter - gas, water, electric, steam, BTU, and even rain gauge. We also deploy virtual meters where we have the data and real meters are cost prohibitive.

We have deployed 130 gas, water, & electric meters for the Philadelphia Housing Authority. 434 gas, BTU, steam, & electric meters for Temple University.

Operator Training

With all this new digital technology, building operators need better training. Intellimation, along with the City University of New York https://www.cunybpl.org/ has received a grant from the Department of Energy to develop a training / support / knowledge platform to provide an online, on demand, perpetual learning environment for building operators. The first version will be piloted this fall for DC DGS building operators.

Initial, Retro, & Continuous-Commissioning

Oftentimes, a building automation system was not programmed and/or commissioned properly, or sensors (inputs) or actuators (outputs) have failed and the BAS is not functioning as intended, or a component of the HVAC equipment has failed. A monitoring based commissioning (MBCx) process uncovers faulty HVAC equipment and/or BAS control. Automated Fault Detection and Diagnostics (AFDD) technology is used to assist the MBCx process. Broken equipment, sensors, actuators, or faulty programming are repaired, and optimized sequences are added to allow the building to run optimally and automatically.

Our Process

Buildings are full of hidden energy savings potential that can be uncovered with the right analysis. Intellimation’s process combines sophisticated energy and BAS system monitoring, using advanced software tools, with advanced retro-commissioning (RCx) practices with the aim of providing substantial and persistent energy savings. Our process combines Man and Machine in a deep dive into your building's performance. Our domain experts, leveraged with the best software analytics tools, will uncover faults/anomalies/inefficiencies, and develop energy efficiency measures (EEM’s) or optimization strategies.

1. Connect the buildings energy meters and BAS data to a trending & archiving platform. This may involve data integration for legacy or proprietary BAS systems

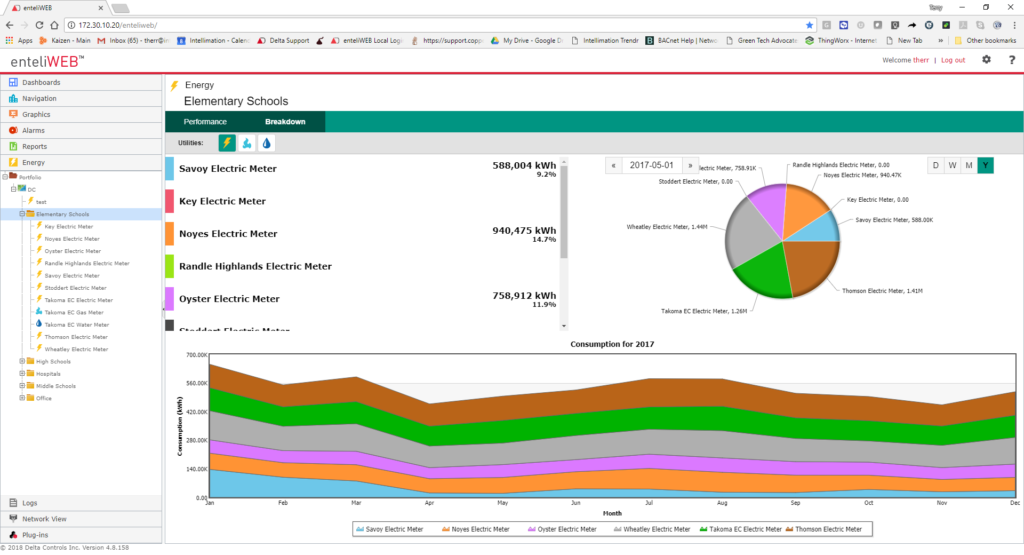

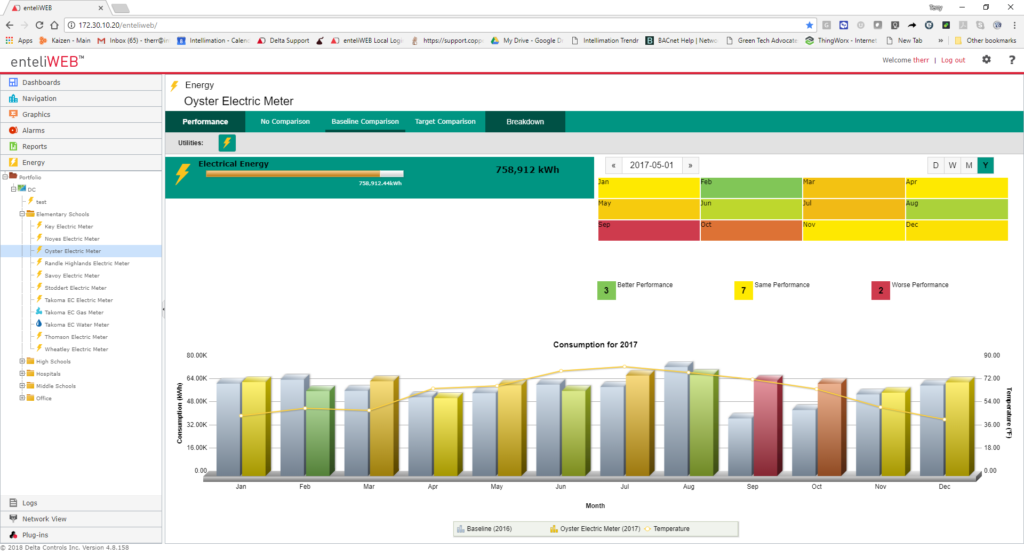

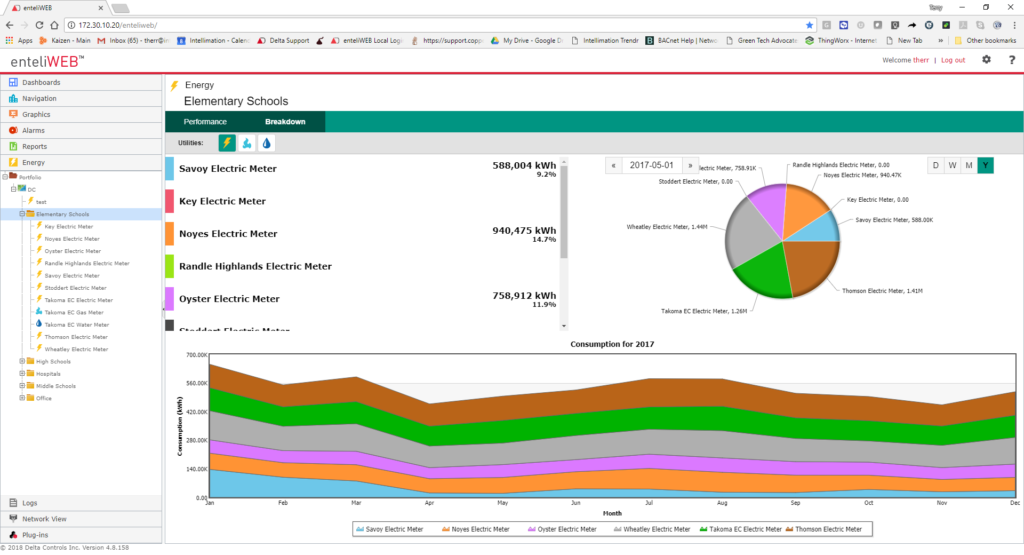

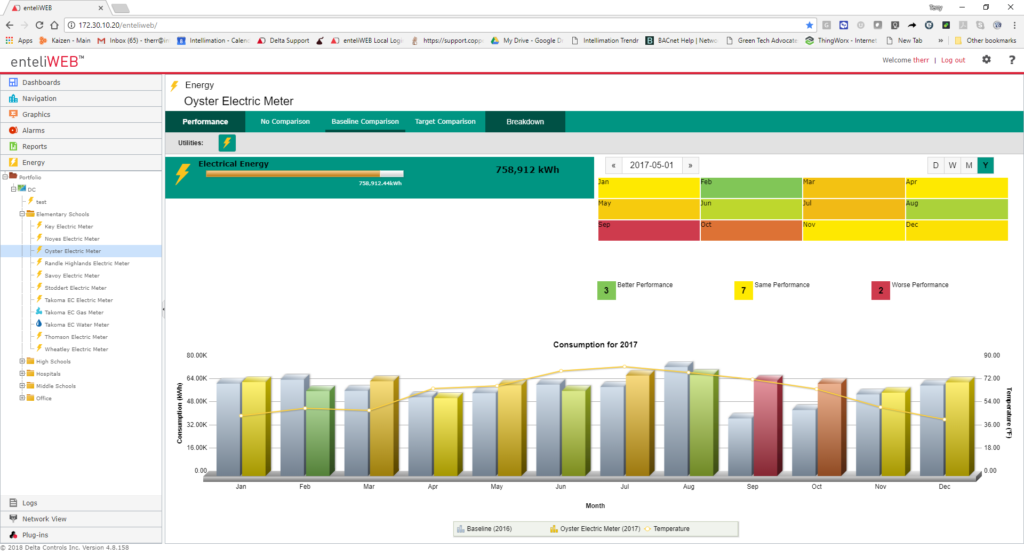

2. Deploy the analytics software (we use several and choose the best product for your building). This includes the development of summary dashboards, reports, and KPI’s (key performance indicators) and automated fault detection and diagnostics / analytics - accessible from any connected device - PC, tablet, or smartphone.

3. Our team of energy, BAS, & HVAC systems analysts, reviews BAS & mechanical drawings, and the output of the analytics software, in order to understand the building - how it was intended to operate, how it is operating, and how it should or could be operating. Often this step includes one or more site visits to get eye-on the mechanical systems to substantiate what the data is indicating.

4. Compile a list of problems or faults, and opportunities for optimization (advanced controls strategies), and present this to the building owner/operators.

5. Help correct the problems/faults and implement approved optimizations. Optimizations include programming/reprogramming and commissioning new control strategies like Optimum Start, AHU/RTU supply temperature and pressure reset, improved economizer, chilled water temperature and pressure reset, etc. Many of these sequences are derived from ASHRAE 36 Advanced Sequences of Operations.

6. Measure and verify the results.

7. The analytics tool continually monitors the system and alerts on any degradation in performance. We provide ongoing support / coaching for building operators.

2. Deploy the analytics software (we use several and choose the best product for your building). This includes the development of summary dashboards, reports, and KPI’s (key performance indicators) and automated fault detection and diagnostics / analytics - accessible from any connected device - PC, tablet, or smartphone.

3. Our team of energy, BAS, & HVAC systems analysts, reviews BAS & mechanical drawings, and the output of the analytics software, in order to understand the building - how it was intended to operate, how it is operating, and how it should or could be operating. Often this step includes one or more site visits to get eye-on the mechanical systems to substantiate what the data is indicating.

4. Compile a list of problems or faults, and opportunities for optimization (advanced controls strategies), and present this to the building owner/operators.

5. Help correct the problems/faults and implement approved optimizations. Optimizations include programming/reprogramming and commissioning new control strategies like Optimum Start, AHU/RTU supply temperature and pressure reset, improved economizer, chilled water temperature and pressure reset, etc. Many of these sequences are derived from ASHRAE 36 Advanced Sequences of Operations.

6. Measure and verify the results.

7. The analytics tool continually monitors the system and alerts on any degradation in performance. We provide ongoing support / coaching for building operators.